Key features

Enables continuous monitoring and vibration reading analysis

Insightful analysis capabilities from the eMaint condition monitoring software

Long battery life via smart battery management

Customizable and auto-generated thresholds based on machine type

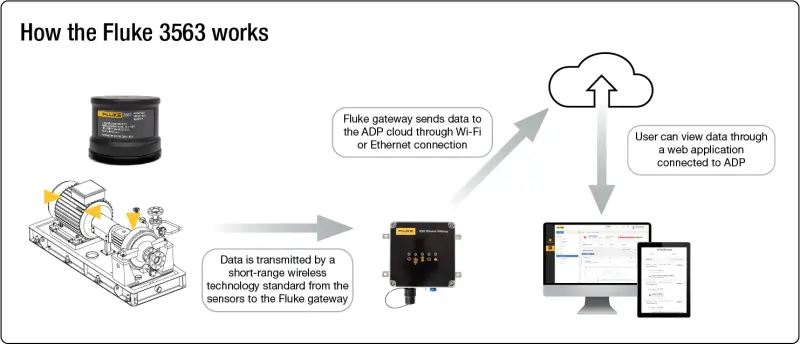

Dual network capabilities for Wi-Fi and Ethernet

Interested?

Find out more...

Fluke 3563 Analysis Vibration Sensor system

The Fluke 3563 combines a high-frequency piezoelectric sensor and insightful software analytics, enabling maintenance teams to regularly monitor and analyze vibration readings for a facility’s production-critical assets. Its smart battery management lets maintenance pros determine the data transmission rate and adapt and extend the sensor battery’s life while still getting the data required.

The sensor’s eMaint condition monitoring software application includes customizable frequency band measurements, automatically generated thresholds based on asset details, trend visualization, and frequency identification graphs. These views enable users to determine which fault is causing a problem to an asset and the cause of the fault. With this analysis, users can evaluate critical next-step actions to take. The result is extended peak operating performance and more efficient maintenance team use – delivering increased business value from maintenance operations.

Combined with setup and vibration training services, the Fluke 3563 can be implemented seamlessly into existing plant operations while yielding the efficiency benefits promised by condition monitoring and practical leverage of the IIoT.

The Fluke 3563 Analysis Vibration Sensor system is a solution that seamlessly combines three parts: hardware, software, and service. The one-on-one setup process includes personalized assistance from Fluke Reliability experts, ensuring successful configuration, commissioning, and installation.

Download more information

Flyer

Brochure

-

![]() eMaint Condition Monitoring Software

eMaint Condition Monitoring Software

Brochure

-

![]() Fluke 3563 Services Brochure

Fluke 3563 Services Brochure

Brochure

-

![]() Fluke 3563 Analysis Vibration Sensor

Fluke 3563 Analysis Vibration Sensor

Brochure

-

![]() 3563 Featured Services | Service Brochure

3563 Featured Services | Service Brochure

Brochure

-

![]() Fluke 3563 Analysis Vibration Sensor | Quick start with built in threshold

Fluke 3563 Analysis Vibration Sensor | Quick start with built in threshold

Brochure

-

![]() Fluke 3563 | Dual Network Capabilities | Tech paper

Fluke 3563 | Dual Network Capabilities | Tech paper

Brochure

-

![]() Fluke 3563 | Customized Data Capture Configuration |

Fluke 3563 | Customized Data Capture Configuration |

Technical Data

Manuals

Application Notes

Whitepaper

-

![]() Why Vibration Monitoring and Analysis are Essential

Why Vibration Monitoring and Analysis are Essential

Whitepaper

Vibration monitoring makes it possible to detect and diagnose problems before they become severe. Using vibration monitoring, maintenance teams can identify machine faults and take action when it makes the most sense.

PRUFTECHNIK Maintenance Technology Service Inc.

PRUFTECHNIK Maintenance Technology Service Inc.